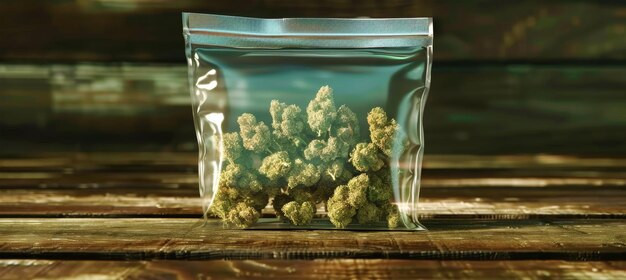

Cannabis Packaging Ensuring Product Safety and Composition Leading Company Announces New Initiatives

views

History of Cannabis Packaging

As cannabis legalization efforts have grown over the past couple decades, the need for product testing has also expanded. Cannabis has long been tested for various levels of active ingredients like THC and CBD, but the focus was narrow. Early testing primarily aimed to prove levels of psychoactive THC so products could be properly labeled. However, legalization brought increased demand for a wider range of tests to build consumer confidence and compliance.

The first widespread testing programs developed in states with medical cannabis laws in the late 1990s and 2000s. These initial efforts often focused on pesticides, heavy metals, and microbiological contaminants that posed health risks. As more states legalized adult-use cannabis, testing expanded further to cover additional compounds and provide detailed cannabinoid and terpene profiles. Now, comprehensive testing analyzes over 200 different compounds to ensure product quality, consistency, and compliance with varying state regulations.

Contaminant Testing

Testing for harmful contaminants like pesticides, heavy metals, mildew, and bacteria is a core part of any Cannabis Packaging program. Especially for medical patients or regular consumers, it's important to know a product is free of microbes, toxins, and pollutants that could cause health issues. Contaminant tests typically screen for:

- Pesticides - Cannabis can accumulate residues from unapproved pesticides, many of which are carcinogens and neurotoxins. Testing identifies any banned chemical pesticides over legal limits.

- Heavy Metals - Products are examined for unsafe levels of lead, cadmium, arsenic and other heavy metals that may accumulate in soil and plants. Over time these can build up in the body.

- Microbiologicals - Samples are cultured and examined under microscopes to check for counts of total yeast and mold, as well as pathogens like Salmonella and E. coli that indicate improper cultivation or processing techniques.

- Residual Solvents - Some solvents like butane, hexane or propane may remain after extraction if not completely purged. Tests ensure residues fall under accepted safety thresholds.

Identifying contaminants gives producers information needed to improve practices while reassuring consumers the products they purchase are clean and non-toxic overall. It plays a key role in ensuring cannabis is grown, manufactured and distributed responsibly.

Cannabinoid & Terpene Profiling

Another core facet of Cannabis Packaging analyzes a product’s cannabinoid and terpene composition. These chemical profiles are important for:

- Product Consistency - Laboratories test multiple samples from each harvest or production run. This verifies the cannabinoid and terpene content falls within an acceptable range batch to batch. Buyers know what they’re getting.

- Efficacy and Effects - By understanding a product’s THC, CBD, CBG, terpinolene and other levels, patients can find strains tailored to their conditions while recreational consumers learn expected effects.

- Compliance - State regulations often include limits for particular cannabinoids or require lab reports verifying levels stated on package labels. Profiles prove everything is legal and accurately represented.

- Quality Improvement - Producers use testing feedback to optimize growing conditions, harvesting times and extraction methods, ultimately honing their craft.

New cannabinoids and the entourage effect guarantee profiling will remain an essential testing facet. Laboratories provide critical insights into how hundreds of compounds work together in each product.

Specialized Testing Categories

Beyond broad contaminants and cannabinoid testing, laboratories also incorporate various other analysis types depending on needs:

- Potency Testing - Quantifying precise THC, CBD and other cannabinoid levels is required in many states and important for proper dosage.

- Terpene Analysis - Understanding a product’s full terpene spectrum has become valuable for replicating particular medical or recreational effects.

- Residual Solvent Testing - Some concentrates require in-depth residual solvent analysis given riskier extraction methods used.

- Label Claim Verification - Products ed for particular conditions undergo tests to substantiate any medical or wellness related statements.

- Shelf-life Studies - Stability testing helps establish optimal packaging and storage requirements as cannabis products take on various shelf-life profiles.

The industry matures, specialized areas like these will expand testing benefits and push quality assurance standards ever higher. Overall testing provides extensive insights and proof needed for regulators, producers and consumers alike. It remains essential for building trust in legal s.

For More Insights Discover the Report In language that Resonates with you

About Author:

Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement.

(LinkedIn- https://www.linkedin.com/in/priya-pandey-8417a8173/)

Comments

0 comment