views

Technology is moving fast. From smartphones and electric cars to smart homes and factory machines, today’s devices need something important to run—power. And at the heart of all this power is a tiny but essential component: the ac dc power supply.

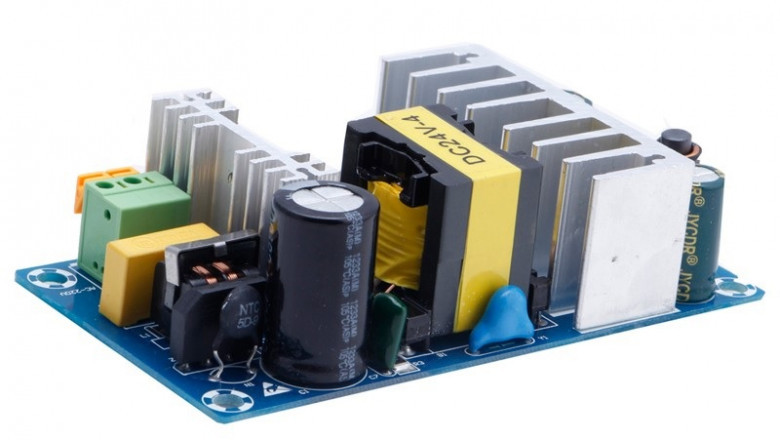

This device quietly turns electricity from the wall (which comes in as AC) into a form that electronics can actually use (DC). It might not look like much, but without it, nothing works. And as our gadgets get smaller and smarter, designing a power supply that keeps up has become a real challenge.

Let’s take a look at the biggest problems engineers face—and the clever new ways they’re solving them.

What Is an AC-DC Power Supply?

In simple terms, an ac dc power supply takes electricity from your outlet (AC, or alternating current) and turns it into the kind of electricity that most electronics need (DC, or direct current). This process involves a few steps: smoothing out the power, controlling the voltage, and making sure everything is safe and stable.

Sounds simple, right? But doing this well—especially in a small, modern device—is not easy.

The Main Challenges Engineers Face

1. Making It Energy Efficient

Energy efficiency is super important these days. Devices need to use less power, even when they’re just sitting idle. And there are strict energy rules in many countries that manufacturers have to follow.

If a power supply isn’t efficient, it turns too much energy into heat instead of useful power. That heat can be a problem, especially in smaller gadgets.

To solve this, engineers are using smarter designs and parts that waste less energy and work better even when the power demand is low.

2. Keeping It Cool Without Fans

As gadgets shrink, there’s less space for cooling systems like fans or big metal heatsinks. But power supplies still generate heat, and that heat needs to go somewhere.

New materials like Gallium Nitride (GaN) and Silicon Carbide (SiC) are making a big difference. These materials let power supplies run cooler and more efficiently. Engineers are also designing circuit boards in better ways to help spread out the heat.

3. Reducing Electrical Noise (EMI)

When power supplies switch power really fast (which helps make them smaller and more efficient), they also create noise—called EMI (electromagnetic interference). This noise can mess with nearby electronics.

To keep things quiet, engineers use special layouts, filters, and shielding. They also use software tools to test for these issues before building anything, which saves time and money.

4. Making Sure It’s Safe

Safety always comes first, especially when electronics are connected to things people touch. Engineers need to make sure the high-voltage parts of the power supply are safely separated from the rest.

New techniques, like digital isolation, make it easier to keep devices safe while using fewer parts. Fewer parts also mean smaller, simpler, and more reliable designs.

5. Making One Power Supply Work Everywhere

Devices are sold all over the world, and power outlets are different in every country. Some use 110V, others 220V—some even change between the two.

To handle this, power supplies need to work across a wide voltage range. Designers now use smart chips that can adjust how the power supply behaves depending on the input. This way, the same device can be sold worldwide without needing different models.

Smarter Tools and Better Designs

Today’s engineers use advanced software to design and test power supplies before they ever build a prototype. These tools help find problems early and make the design process much faster.

More and more, power supplies use digital controllers instead of old-fashioned analog parts. These smart chips give better control, can adjust automatically, and can even report problems or send data to other systems.

New Materials Are Changing Everything

Materials like GaN and SiC are a big deal in the world of power supplies. They’re faster, more efficient, and cooler than regular silicon. That means engineers can build smaller, more powerful devices without the heat problems.

GaN is now common in fast phone chargers, while SiC is great for bigger systems like electric cars or solar power setups.

Working Together with DC-DC Power Converters

In many systems, the ac dc power supply is just the first part. Once it turns wall power into DC, another piece called a dc-dc power converter often steps in. This part adjusts the voltage to exactly what different parts of the device need.

It’s important that both parts work together smoothly to keep things stable and efficient—especially in devices that can’t afford power glitches, like medical tools or battery-powered gear.

Smart Features and a Greener Future

Power supplies are getting smarter. Many now include features like energy-saving adjustments, automatic error detection, and even internet connectivity for remote monitoring.

This means they can respond to changes, warn about issues, and use less energy all great for performance, reliability, and the planet.

Final Thoughts

Creating a great ac dc power supply isn’t easy anymore. With higher energy standards, smaller devices, and smarter tech, engineers face more pressure than ever. But with new materials, better tools, and fresh ideas, they’re building power supplies that are efficient, reliable, and ready for the future.

Whether it’s a phone charger or an electric car, one thing’s for sure: without a smart power supply behind it, nothing works.

Comments

0 comment