Mitolyn Ingredients Label

-

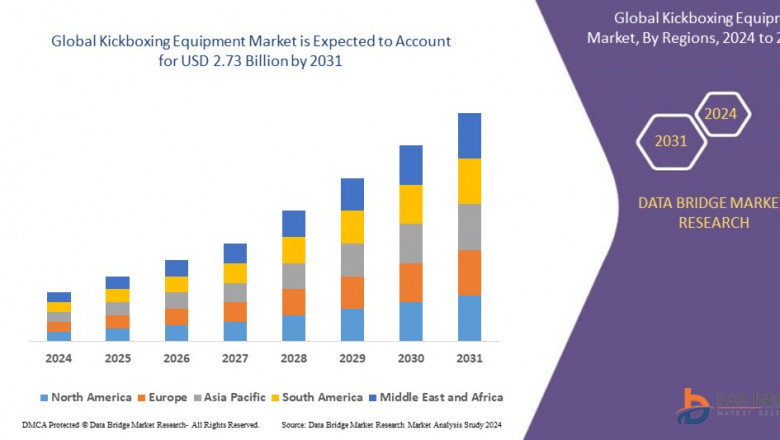

Data Bridge Market Research Data Bridge Market Research analyzes that the g...

Oil & Gas Pipeline market to expand at 8.3% CAGR (2025–2035), rising fr...

Legal representation is a cornerstone of justice, yet for many people aroun...

Rust can be a persistent and costly problem, especially when it affects mac...

This post delves into the future of human-robot interaction and the role hu...

The ultra fast speed you need is here with SATHYA Fibernet, Wifi Connection...

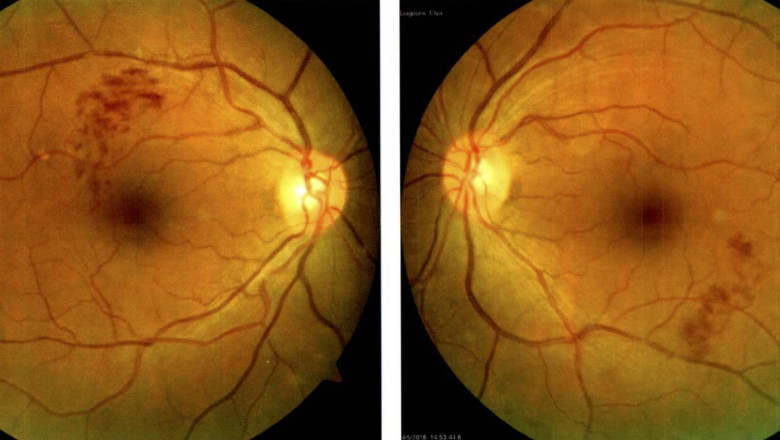

The Retinal Vein Occlusion Market is estimated to be valued at USD 2.40 bil...

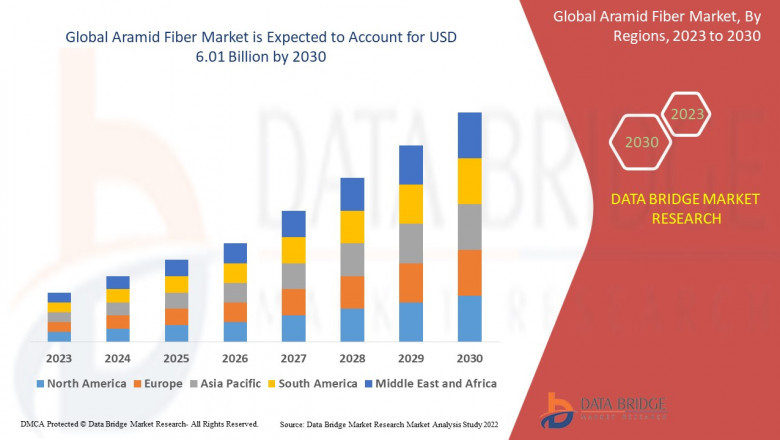

Data Bridge Market Research analyses that the aramid fiber market is expect...