How AI Is Changing Software Changing Techniques

-

Tata Sierra Launch Date: A Legendary Comeback Scheduled for 2025

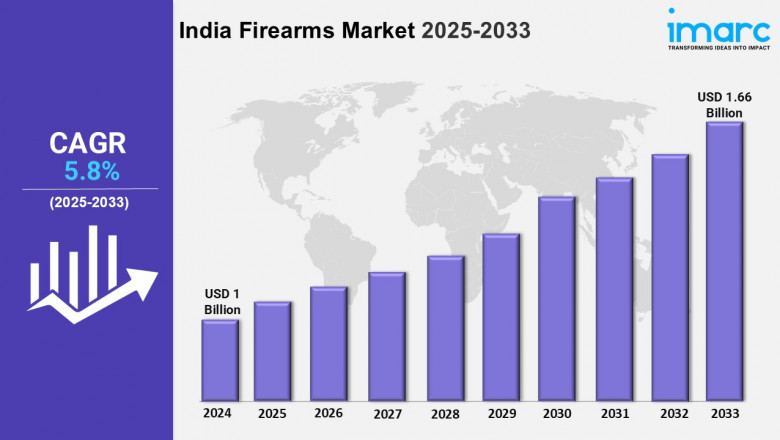

The India firearms market size was valued at USD 1 Billion in 2024 and is e...

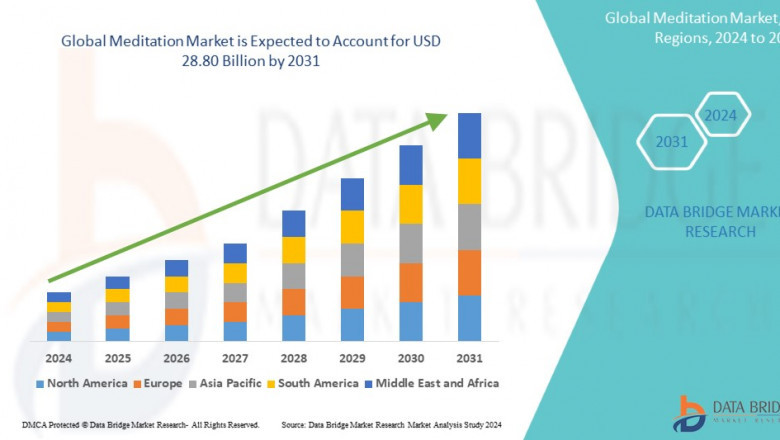

The global meditation market was valued at USD 8.78 billion in 2024 and is...

london airport transfer heathrow to Gatwick

Explore key trends and strategic insights shaping the global butyl rubber m...

The Global Telemetry Market size is Anticipated to Exceed USD 512.25 Billio...

Discover how Quality Handyman Services San Luis Obispo fix plumbing problem...

Discover the top 10 online booking tools for 2025, featuring Satguru Travel...