Klap: The AI Video Editing Tool Revolutionizing Social Media Content Creation

-

The power semiconductor market is estimated to be valued at USD 55.03 Bn in...

During the forecast period of 2025 to 2032 the market is likely to grow at...

Explore how crypto hedge bots help businesses manage market volatility. Thi...

The Global Nickel Metal Hydride Battery Market is estimated to be valued at...

Do you wish to learn and make money in 2025? Find the best courses that inc...

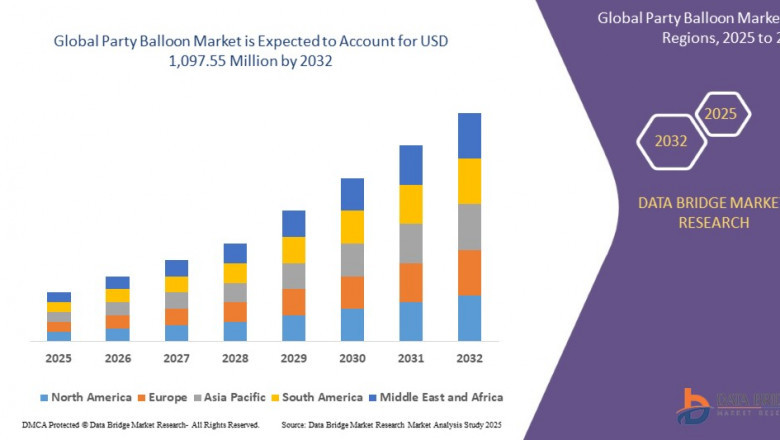

party balloon market size was valued at USD 699.10 million in 2024 and is p...

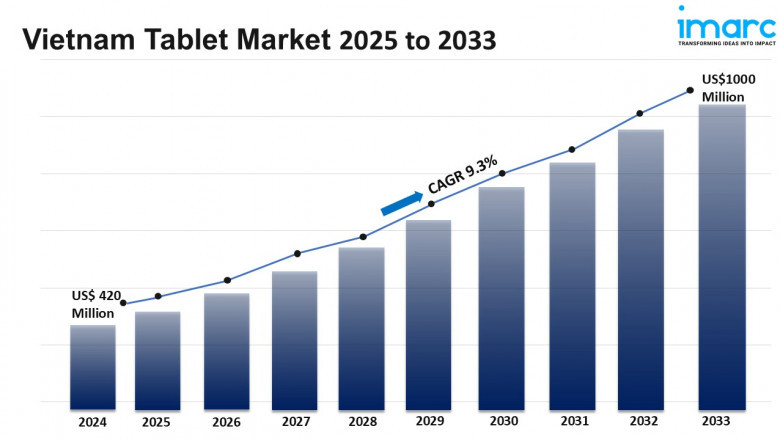

The Vietnam tablet market size reached USD 420 Million in 2024. Looking for...

Get ready for IIT JAM Maths triumph! To assist students in grasping the com...