views

In today’s advanced electronics world, where precision, speed, and reliability are everything, the demand for hybrid multilayer PCBs is rising fast. These complex circuit boards are the foundation of many high-performance systems used in aerospace, defense, medical devices, and telecommunications.

But here’s the truth: Even the most cutting-edge hybrid multilayer PCB design can fall short without one crucial skill—wire bonding expertise.

Let’s explore why wire bonding experts are essential to successful hybrid PCB projects and how they help deliver performance that goes beyond expectations.

Understanding Hybrid Multilayer PCBs

A hybrid multilayer PCB is a circuit board that combines multiple materials (like ceramic, polyimide, or FR4) and layers into a single, compact board. These PCBs are built to handle high speeds, extreme temperatures, and dense component placement, making them perfect for advanced electronics.

Unlike standard PCBs, hybrid boards are more complex, both in design and in manufacturing. They often include surface mount components, embedded passives, and require intricate interconnections between layers.

And this is exactly where wire bonding becomes critical.

What Is Wire Bonding?

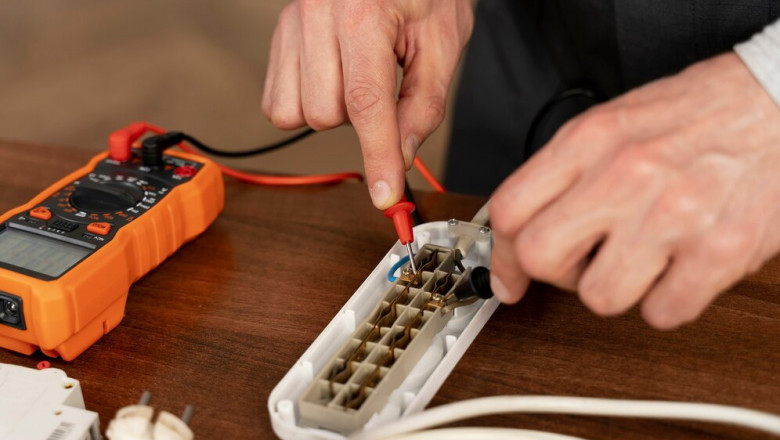

Wire bonding is the process of connecting a tiny wire, often gold or aluminum, between a semiconductor chip and a substrate or another component. It’s used to create electrical paths in microelectronic assemblies and is vital for many hybrid PCBs where traditional soldering isn’t possible.

The precision required in wire bonding is intense. These wires are often thinner than a strand of human hair, and the bonding process must be spot-on to avoid defects or failure.

Why Wire Bonding Expertise Matters

1. Delivers Electrical Precision

In hybrid multilayer PCB, high-frequency signals, low noise, and clean power lines are non-negotiable. Wire bonding ensures low-resistance and low-inductance connections, helping your circuit maintain its electrical integrity.

At Hybrid-Tek, our wire bonding experts know exactly how to manage signal paths and ensure reliable electrical performance in every bond.

2. Supports Compact, High-Density Designs

As devices shrink, PCB real estate becomes tight. Wire bonding allows vertical connections, letting engineers stack components and optimize space without sacrificing performance.

This level of compactness is only achievable when experienced professionals handle the job, ensuring each bond is secure, precisely placed, and free from stress.

3. Prevents Costly Failures

Improper bonding can lead to open circuits, short circuits, or temperature-related failures. In critical industries like medical or aerospace, a single faulty bond could mean total system failure.

Working with seasoned wire bonding experts means your PCB is built with reliability and risk management in mind. They test, inspect, and verify each bond to meet the highest quality standards.

4. Enables Hybrid Material Compatibility

Different PCB materials expand and behave differently under heat. Wire bonding allows flexible connection strategies that can accommodate these differences—something standard soldering can't always handle.

At Hybrid-Tek, we design and execute custom bonding solutions tailored to the specific materials used in your hybrid multilayer PCB.

5. Speeds Up Prototyping and Reduces Iterations

Experienced bonders can spot design flaws early and suggest layout improvements. This feedback loop between the wire bonding team and the design engineers helps fine-tune the PCB faster, cutting down on costly revisions and delays.

With our in-house bonding and engineering teams, Hybrid-Tek delivers faster turnaround from concept to functional board.

Why Choose Hybrid-Tek?

We combine state-of-the-art PCB manufacturing with deep wire bonding experience—all under one roof. Whether you're building high-reliability military systems or ultra-compact medical devices, we provide:

● Precision micro wire bonding (ball and wedge bonding)

● In-house inspection and quality control

● Custom hybrid multilayer PCB design support

● Rapid prototyping and high-volume production

Our expert team ensures your hybrid PCBs are not just functional, but built to last.

Final Thoughts

A hybrid multilayer PCB is only as strong as its weakest connection. And in most cases, that connection is a wire bond.

Don’t trust your complex designs to generalists. Trust wire bonding experts who understand how to connect every detail—literally and technically.

For More Information You Can Contact this mail-: info@hybrid-tek.com or you can call this number directly : 6092593355

Read More Blogs Here:

What Is Thick Film Circuit Fabrication? A Complete Guide

Comments

0 comment