views

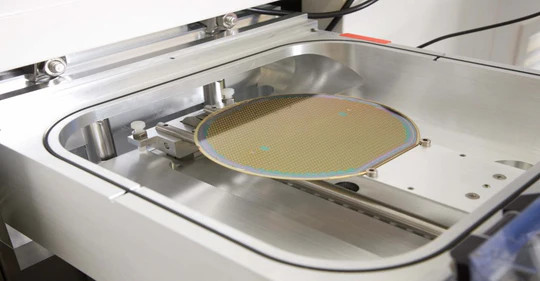

Modern energy systems require more power management and improved efficiency. Industries now concentrate on moving from outdated materials to newer ones that can manage higher power with less energy loss. SiC High Voltage wafers are one such material. Systems requiring rapid switching and excellent performance now frequently employ these wafers.

The Evolution of Energy Systems

Old power systems relied on silicon-based parts. In the past, they performed well. But they currently find it difficult to satisfy the needs of today's power-hungry applications. Electric cars, solar systems, and wind turbines all require quicker, more robust, smaller power devices, for example.

Furthermore, businesses are working to lower heating and energy loss. New materials such as silicon carbide assist in both. They permit improved power flow and can operate at greater voltages and temperatures without failing.

What Distinguishes SiC Wafers?

Silicon carbide is what SiC means. It is a consistent and robust substance. Under severe circumstances, it outperforms silicon. For instance, it can manage quick switching and high voltages without overloading.

Unlike conventional silicon wafers, SiC wafers can transport more power with less area. This enables more effective and compact power modules. For electric cars and renewable energy systems, that is quite advantageous.

They are also thermally conductive. This indicates that they labour more yet remain cooler. This allows designers to reduce cooling equipment, hence saving space and money.

Real Advantages in Energy Systems

Energy systems require small dimensions, little energy loss, and quick switching. SiC wafers satisfy all these requirements. They aid to lower switching loss, hence using less power.

They also let devices operate at high frequencies. This helps to shrink the size of other system components and transformers. Thus, systems get simpler to control and lighter.

Though SiC wafers are more expensive initially, they aid reduce maintenance and save energy over time.

Where Do They Find Application?

Many industrial and energy systems currently employ SiC high-voltage wafers. Their capacity to withstand high voltages and temperatures makes them a good alternative for current power requirements.

Solar inverters are one of the main applications. These devices turn DC electricity from solar panels into AC power used in households and companies. During this conversion, conventional inverters waste energy. With SiC wafers, on the other hand, the process gets quicker and more efficient, resulting in far less energy loss. This increases the total solar panel output.

In EV chargers, these wafers lower heat build-up and hasten the charging process. They also enable lighter and smaller charging devices, which simplifies installation. Power control systems inside the EVs themselves employ SiC wafers. They help lower the requirement for large cooling systems and increase battery life.

Furthermore, industrial motors employ them to obtain improved energy savings and speed control. These motors generally operate all day; therefore, cutting power waste is a major advantage.

These wafers are also used by high-speed trains for quicker and smoother functioning. Using SiC wafers in data centres—where thousands of computers operate non-stop—helps to lower energy usage and cooling requirements.

Their widespread use reveals how crucial they are growing in relevance across many energy systems.

Silicon Carbide and Diodes

High-voltage systems rely significantly on the diode. Conventional diodes cannot tolerate high heat well and waste more energy. On the other hand, Silicon carbide Schottky diodes provide a superior choice.

They endure more stress, switch faster, and waste less power. These diodes also assist in creating more robust systems that don't collapse quickly.

Furthermore, they are more consistent in both low and high temperatures. For locations with severe temperatures or continuous use, this is crucial.

Support from Indian Companies

Several Indian businesses currently actively contribute to SiC growth. For example, Quest Semi India is working to provide better solutions using these materials.

Their emphasis is on providing premium parts that satisfy world standards. Their efforts help the local economy and lessen reliance on foreign technologies.

This is encouraging for India's energy industry. It reduces costs and increases industrial access to renewable energy.

Long-Term Impact on Energy Use

Every level's power savings can be achieved by switching to SiC-based technologies. Less power waste translates to greater energy for everybody, whether in homes, factories, or cars.

Many professionals say SiC will soon be the standard, even if the technology is still developing. Cost and performance must be balanced.

SiC wafers provide energy systems with new potential by means of improved heat control and quicker switching.

Final Thoughts

Power systems have to operate more intelligently and harder. Materials including SiC High Voltage wafers assist to enable that. They let more electricity flow, reduce energy loss, and extend the life of gadgets.

These systems get even more dependable and effective with the help of Silicon carbide Schottky diodes. Furthermore, indigenous companies such as Quest Semi India are increasing the availability of such technology in the nation.

Thus, as energy demand rises, these wafers are essential for constructing power systems that operate better, quicker, and longer.